Get To Know Our Bi-directional, One-way Clutch

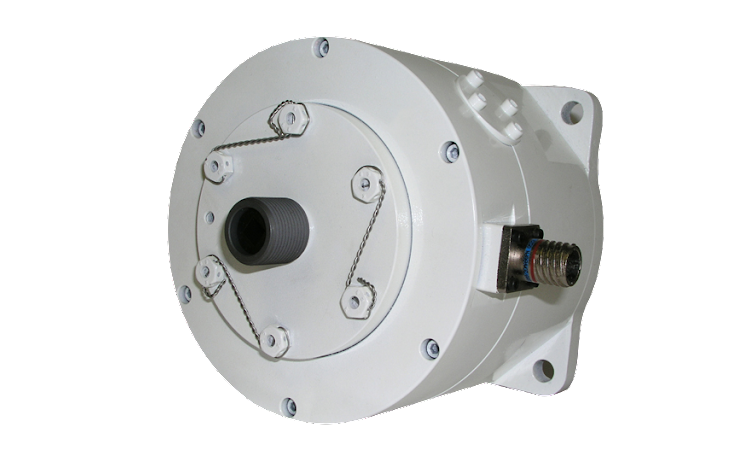

A clutch that is both bi-directional and one-way might sound like a contradiction. But in fact, we offer just such a clutch. As a bi-directional clutch, the MTL can transmit torque from input to output shaft in either rotational direction. And, its one-way functionality prevents output shaft loads from backdriving into your other power transmission components. These capabilities make the MTL bi-directional one-way clutch excellent at sustaining torque overloads and shock loading.

Choose from three standard models with torques ranging from 15 to 120 foot-pounds and bore sizes ranging from ⅞ to 1 ⅞ inches. The clutch’s driving end achieves smooth rotation regardless of the direction of the load, and it is self-locking — made possible by a friction disc and ball ramp design.

Combine Parts To Solve Every Challenge

You can easily integrate the MTL bi-directional one-way clutch with other Carlyle Johnson clutches, brakes and torque limiters, creating lighter and more compact designs depending on the component combination. For example, pair the MTL clutch with a Carlyle Johnson spring-applied clutch for braking, torque limiting and manual driving functionalities — all without having to worry about backdriving.

We can even include a torque limiter as part of the MTL bi-directional one-way clutch. If you place it on the input side, it will limit the driving torque. If you place it on the output side, it will allow slipping in the stationary component if there is an excess load, protecting either upstream or downstream components. Both the internal torque limiter and spring-applied clutch are available customization options. Another option is the ability to set a firm slipping point.

Tailored to Your Specifications

Our experienced engineers can customize the MTL bi-directional one-way clutch to meet your design and application requirements. We can also alter any of our standard products or design an entirely new clutch.

Contact us today for more information.