Friction-Spring Industrial Buffer Designs Reduce Maintenance and Improve Safety for Mining Operations

Mining operations require reliable components to ensure the safety of personnel, equipment and the environment. To prepare ore for shipping, the raw material is transported to cargo holds aboard ships or trains via loaders traveling along a rail track. Industrial buffers are often installed at the end of the track to halt and slow loads in case of brake failure.

Conventional industrial buffers are designed with hydraulic components that require extensive maintenance and can harm the environment. Designing these buffers with friction springs instead of hydraulics provides a maintenance-free and sustainable solution.

The Reliable, Non-Hydraulic Alternative

Emergency buffers need to absorb a tremendous amount of energy — often over 200,000 joules. Friction springs are ideal for this heavy-duty application because they are capable of absorbing such large amounts of energy while providing maintenance-free, environmentally friendly operation.

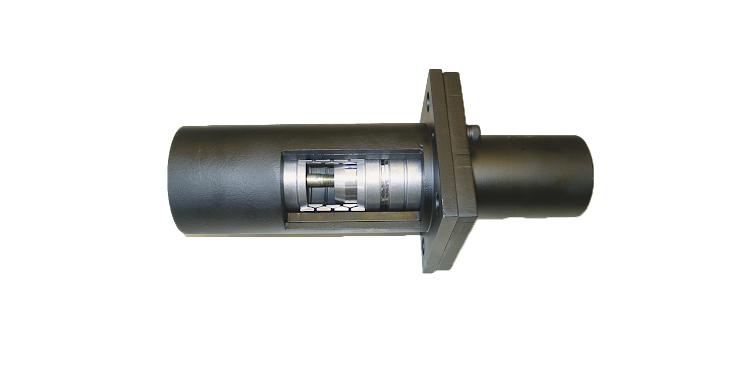

Ringfeder® friction springs can be designed into complete buffer and damping solutions for industrial systems that must absorb enormous forces within a relatively small amount of space. Each complete friction spring column consists of precisely machined inner and outer rings. This design offers a number of advantages compared to conventional damping solutions including:

- High spring work at low weight and volume.

- High damping capability.

- Spring work and damping effect independent from load speed.

- Overload-safe in block position.

- Maintenance-free and temperature-independent.

- Parallel and serial spring arrangements.

- Individual designs for specific use cases.

Because Ringfeder friction springs are designed to make full use of the spring material, both weight and dimensions are kept to a minimum. Our friction springs exhibit 66% damping as standard, so they can quickly absorb energy and completely suppress resonance effects. Through the use of lubricants specific to a given application, we can adjust the damping to values between 33 and 66%.

Whereas hydraulic dampers and springs consisting of synthetic materials are subject to temperature fluctuations that can impact performance, our friction springs feature temperature-independent operation within a range of -20 to +60 degrees Celsius. Within this temperature range, the force-stroke curve of our friction springs doesn’t appreciably change — temperature fluctuations within this range have already been accounted for in the friction spring design.

Exploring a Successful Application

A mining operation in North Brazil previously used hydraulic emergency buffers, but with our friction springs, the operation has reduced its maintenance costs and environmental impact. The two new buffers each consist of three different friction springs — sizes 24201, 19600 and 14000 — in a parallel design. Additionally, the project required the buffers to each absorb 150,000 joules with a 159-millimeter spring deflection.

To provide additional safety, each of the new buffers was designed to absorb 189,000 joules of energy with a preload force of 277 kilonewtons, a maximum spring force of 1,850 kilonewtons and a total spring deflection of 178 millimeters. During regular operation, the emergency buffers would only utilize 90% of their potential.

Learn More

Our friction springs are applicable to a wide range of industrial applications where sudden loads need to be stopped or slowed. Thanks to their durable construction and innovative design, Ringfeder friction springs prove reliable and effective in even the most demanding applications.

Learn more on our product page.