Locking Assembly Replacement Ensures Ball Mill Performance for Cement Production

Maintenance engineers at a cement production facility were recently experiencing repeated equipment failures. Upon investigation, they found the shaft-pinion connection of the ball mill unit was malfunctioning. Specifically, the locking assembly that connected the shaft to the pinion was out of tolerance with an abnormally high run-out of 300 to 400 micrometers (μm).

Malfunctions caused by the eccentricity of the radial run-out were leading to equipment breakdowns that required the cement operation to spend a significant amount of money on ball mill maintenance.

Engineers attempted to remove and reinstall the locking device, hoping it would reduce the high run-out value. However, they were challenged to make the repair when they discovered the locking assembly could not be removed — even with the support of the ball mill manufacturer and locking assembly supplier.

Locking Assemblies to the Rescue

The cement operation contacted Ringfeder to assist. As part of our initial analysis, we found the locking assembly could not be unlocked due to irreparable damage. It took five engineers an entire day to remove the damaged locking assembly, which was broken into several pieces.

After the shaft and the pinion were thoroughly cleaned, engineers used a Ringfeder locking assembly to mount and connect the two components. This successful replacement reduced the run-out value to an acceptable 80 μm and minimized vibrations.

When specifying a locking assembly, it is also important to consider whether axial displacement is necessary and if the assembly must be self-centering. In addition, it is crucial to determine the required transmissible torque for an application. To this end, our website has a helpful selection tool to help you choose the right locking assembly based on these factors.

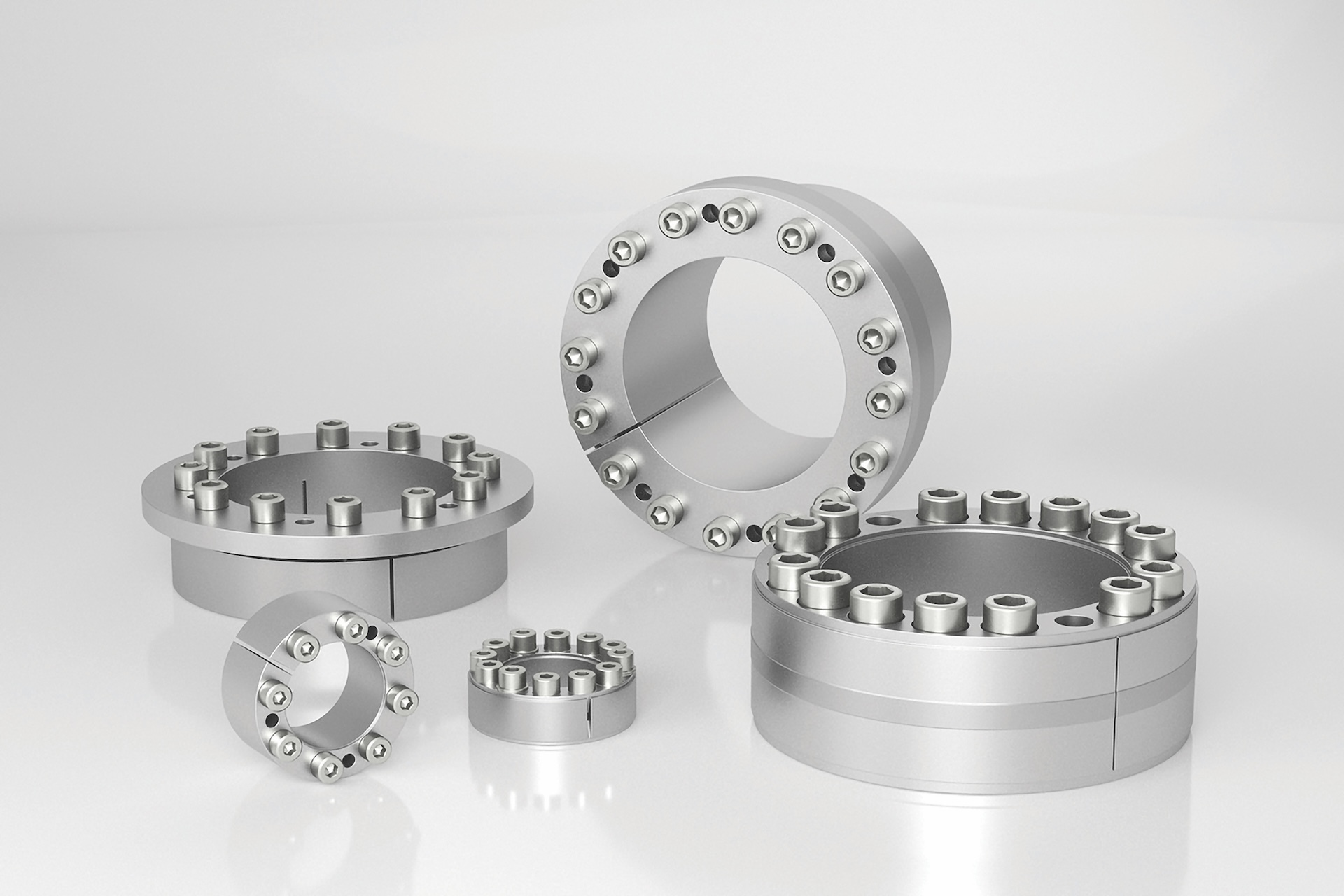

Keyless shaft-hub locking assemblies are one of our specialties. Here’s an overview of what kinds of locking assemblies we offer:

Self-centering. These locking assemblies offer extremely precise concentricity, with the maximum allowable error confined to 0.04 millimeters (mm). Self-centering locking assemblies are often found in rotary pumps and high-precision machine tools.

Zero axial displacement. These locking assemblies are ideal whenever displacement would negatively affect the connection. These units are often implemented in machine tools, helical gear wheels, rotary table drives, pumps and brake disc mountings.

Low surface pressure. When requiring minimal tension between joined components, locking assemblies with low surface pressures are ideal. These units are mainly used in hubs with extremely thin walls or with low yield strength. Hubs that consist of gray cast iron or aluminum are also appropriate applications for these locking assemblies.

Learn more on our product page.