AFS Brake Delivers Fast, Reliable, Positive Braking Action

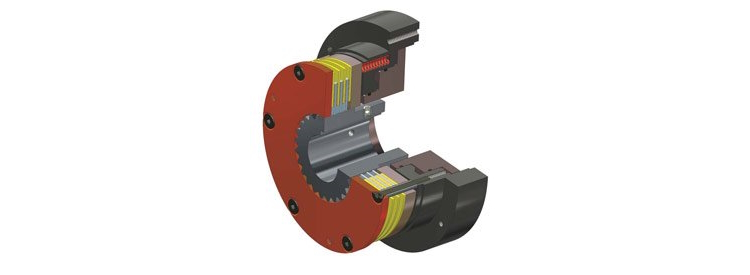

Medium-duty applications — like starting and stopping medical diagnostic equipment and robotics — require reliable, precision-engineered brakes. Our AFS Multiple Disc Air/Hydraulic Spring Set Brake meets these requirements, delivering high-performance, fast and reliable action. Here’s how it works:

The AFS applies braking torque when air or hydraulic pressure is removed from the piston chamber. When the piston chamber loses pressure, compression springs clamp multiple friction discs, which are located between the pressure plate and stationary end plate. This design ensures a consistent holding force. When air or hydraulic pressure is applied, the brake releases and is free to rotate.

When disengaged, the multiple friction discs are uniformly spaced by a unique separator spring design that ensures separation of the rotating friction discs regardless of the brake’s orientation. This feature virtually eliminates parasitic drag, extending the brake lifespan and reducing disengagement times.

Our AFS brake delivers high torque in a small space and has low inertia, delivering fast and reliable positive-braking action. It’s capable of torque outputs from 15 to 1,000 pound-feet and can operate in both wet or dry environments. It also features a universal floating hub for interior or exterior shaft attachment.

Match Your Exact Specifications

It’s easy for us to modify a design to meet your exact requirements. We can produce custom brakes with torque capabilities up to 3,200 pound-feet, as well as AFS brakes for frequent, high-energy stops or extremely high- or low-speed braking applications.

Our engineers can alter standard units or completely custom design a brake to meet your needs. Some customization options available include:

- Low backlash models

- Covers for harsh environments

- Custom designs and alterations

Visit our product page or contact us to find out more.