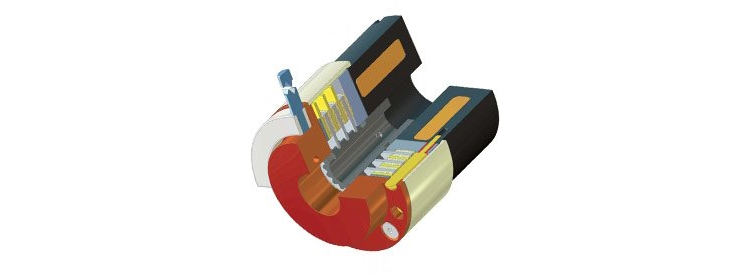

HTB Brakes Achieve High Torque in a Small Package

Reaching the required amount of torque in space-constrained power transmission systems — which is often the case for applications like servo drive brakes or emergency stopping brakes — can sometimes be difficult. Fortunately, our HTB high-torque, spring-set brake excels in these and other tough applications, thanks to quality materials, precision engineering and a compact design.

Let’s take a closer look at this component.

An Overview of the HTB

The HTB electric brake features a multiple floating disc design that disengages when power is applied to the brake coil and engages when that power is removed. It is a cost-effective solution when you need extremely high torque in a very compact package.

The brake’s components also require minimal power for release, reducing engagement and disengagement times, as well as lowering drag torque. For even faster engagement and disengagement times, you can use the HTB in conjunction with a standard CEC power supply.

Common applications for the HTB include head positioning in medical imaging machines, as well as stopping and holding tasks in mechanized handling equipment.

Customize Your Brake

While we designed the HTB as an off-the-shelf solution for your braking needs, its modular design enables easy customization, enabling us to quickly design and manufacture units that meet your exact specifications. For example, we can include manual release features, environmental protections and friction-pad wear indicator switches. Other available modifications include:

- Different voltages

- ON/OFF brake status indicator switch

- Integral heater for extreme environmental conditions

- Sealed cover

- Custom designs and alterations

Whether customizing a standard unit or designing an entirely new brake, our engineering staff is ready to solve your toughest application challenges.

Contact us to learn more.